Using the Truxor© 5000, this low impact method allows aquatic vegetation to be cut from above water level to a depth of 2m.

Desilt waterways using a low impact hydraulically operated dredge pump.

Treat your dirty water on site to legislative requirements - EP Act 1970

Water quality is monitored throughout each stage of your waterways management project to ensure environmental compliance

Using the Truxor© 5000, operated by Australian Aquatic Solutions, weeds/reeds can be cut from above water level to 2m below the water surface. Vegetation is then harvested, transferred to the bank, drained of water and disposed offsite. The amphibious machine combined with low ground pressure allows it to operate in sensitive areas without damage to the environment.

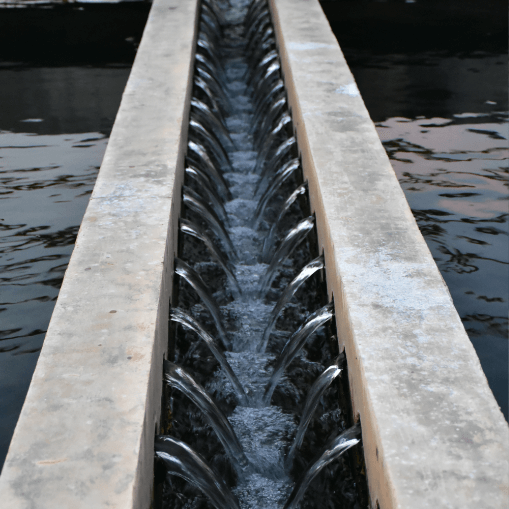

The Truxor© 5000 has the capability to break off and feed the sediment to the pump inlet. There are augers mounted in the suction inlet of the pump to provide the pump with an even flow of sediments. The shroud on the intake feed system helps to minimise turbidity of the surrounding water. Plumes of sediment are directly sucked into the pump. This system eliminates earlier excavation methods that increase turbidity and disturbed aquatic fauna. Sediment is carried via lightweight 100mm cam-linked suction line that is floated from the Truxor© 5000 to the waterways bank. Lay flat delivery line is then used to transport the dredged material to a treatment train system suitable for the scope of works encountered.

A comprehensive water quality monitoring program is conducted on site. Each site will be unique; however the plan will be to ensure the following points will be monitored prior to and during dredging & dewatering activities;

Sample testing of treated water will be conducted hourly. Tests to be undertaken will include; pH, turbidity & temperature. Water monitoring equipment used include; data logger(manta, multi-probe aqua reader). results will be compared to the Sepps (Waters of Victoria)- water quality objectives to ensure legislative requirements are met prior to discharge.

Silt and sediment collected through the dredge enter a fully enclosed treatment train where the sludge comes into contact with an appropriate flocculant (usually Floc Blocs). Floc Blocs are a slow release flocculant that acts to bind together all fine particles (soil, silt and clays) so that they will settle out rapidly leaving clear water. Depending on the nature of the silt being pumped a secondary flocculant or a coagulant may be injected into the treatment train to ensure all sediment is settled out resulting in clean water.

Treated water and sediment enter a geotextile dewatering tube through cam-lock fitting. Dewatering tubes are made of a woven geotextile that collects sediment but allows clean water to seep out through the pores of the geotextile and re-enter the waterway. The sediment held within the tube is then dried out and can be recycled. Alternatively water can be directed to a portable clarifier that allows fine particles to settle using laminar plate technology. Clean water is then passively pumped back into the waterway.

By undertaking vegetation harvesting, dredging, pumping to a dewatering bag and then allowing the treated water to seep out and discharge back into the waterway has numerous benefits including;